Founded in 2007, the Hi-Tec company TEC Microsystems GmbH is based in the prominent Technology Park Berlin Adlershof, Germany. Thermoelectric technologies are our core competence based on almost a decade of analysis, innovative development, product design and numerous successful projects in this field. Specialized in miniature thermoelectric modules (Peltier elements), TEC Microsystems GmbH is a driver of innovation and technological progress, including state-of-the-art analysis techniques. Our customers operate worldwide in industries like optoelectronics, telecom, micro-electronics, space, medical equipment/health care, security systems and fundamental research.

TEC Microsystems GmbH focuses on miniature thermoelectric module developments and manufacturing technologies. Our key advantages are in the practical implementation of innovative technologies and know-how in real TEC manufacturing. Since 2007 TEC Microsystems engineers developed more than 5000 different thermoelectric solutions for customers in the laser and optoelectronics industry.

Our experience and know-how allow us to quickly find and develop the most efficient solutions with thermoelectric technologies.

TEC Microsystems GmbH also successfully uses thermoelectric technologies for small scale green energy harvesting as a seminal strategic component into its business operations.

TE COOLING FOR THE APPLICATIONS

KEY FEATURES AND ADVANTAGES

◻ LD and Superluminescent Diodes

◻ X-Ray and IR- Sensing Applications

◻ Photodetectors

◻ Avalanche Photodiodes (APD)

◻ Focal Plane Arrays (FPA)

◻ Charge Couple Devices (CCD)

◻ More than 5000 TEC types in a range

◻ Advanced HD Assembly Technologies

◻ High-quality Materials

◻ Sn-Sb assembly Solder (Tmelt=230ºC)

◻ 100% Quality Control

◻ RoHS compliant by default

We work directly with engineering teams of our customers and provide advanced thermoelectric solutions optimized for exact application requirements. Our key advantages are in ultra-fast application analysis, world widest range of thermoelectric coolers and great flexibility with TECs manufacturing options.

All thermoelectric modules and related products are designed and developed in our ISO 9001:2015 certified facility in Berlin, Germany.

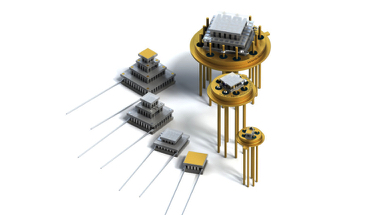

TEC + HEADER = TE SUB-ASSEMBLY

KEY FEATURES AND ADVANTAGES

◻ Minimized risks and expenses

◻ Significant time saving for projects

◻ Single Source for TECs and Headers

◻ Perfect solution for R&D

◻ Optimization for application

◻ More than 5000 TEC types for integrating

◻ High-quality glass-to-metal headers

◻ High-temperature TEC soldering

◻ 100% Quality Control

◻ RoHS compliant by default

The term “thermoelectric sub-assembly” means a thermoelectric cooler mounted into standard or customized package. Thermoelectric sub-assembly is a perfect solution for fast and easy integrating into final application. There is a range of industry standard headers and packages, that are usually used with thermoelectric coolers.

ENERGY HARVESTING SOLUTIONS FOR

KEY FEATURES AND ADVANTAGES

◻ Smart Home

◻ Aviation and Train Monitor

◻ Industrial process control

◻ Automotive Industry

◻ Security systems

◻ Wearable devices

◻ More than 500 standard TEG types

◻ Bulk TE Technology with 400uV/K

◻ Ultra-miniature TEG sizes

◻ Maintenance-free

◻ Long Lifetime

◻ Best Price-Performance Ratio

Thermoelectric harvesting is considered a key component for many future technological applications, like wireless sensor networks, multi-purpose self-organising autonomous (micro-)systems and many others. The key advantages of thermoelectric micro-generators: small sizes, simple scalability; no moving parts, very long operational lifetime – tens of years without maintenance. And the most unique property – the possibility to convert heat into electricity starting from very low temperature differences of just a few degrees.

HEAT FLUX SENSORS KEY APPLICATIONS

KEY FEATURES AND ADVANTAGES

◻ Scientific analysis and research

◻ Agriculture

◻ Climatology

◻ Building engineering

◻ Solar industry

◻ Safety and Security applications

◻ Ultra-high sensitivity

◻ Miniature dimensions

◻ Self-calibration (patented)

◻ Built-in temperature sensor

◻ FET cable and connector

◻ Wide range of types

The advantage of thermoelectric module (TEM) over differential thermocouple is in much higher Seebeck effect (electromotive force), exactly because of semiconductor usage. For example, in usual Copper-Constantan thermocouple the electromotive (EMF) is 38uV/K, while one BiTe P-N pellet pair inside a thermoelectric module provides EMF 400uV/K - ten times higher. This key advantage makes thermoelectric modules very promising to use as heat flux sensors.

DX5100 CONTROLLERS KEY FEATURES AND ADVANTAGES

◻ Bi-directional TEC regulation

◻ Supports NTC and PTC thermistors

◻ Two channels 32W (4Ax8V) each

◻ PID Temperature regulation mode

◻ PID Auto-Tune function

◻ Constant voltage operation mode

◻ Programmable Controllers

◻ PC Controlled and Stand-alone

◻ Network connectivity (max 128 channels)

◻ USB and RS-485 interfaces

◻ Complete LabView Integration

Thermoelectric Controllers of the DX5100 family represent a range of precision-programmed devices (standard and OEM versions) for management of thermoelectric coolers (TECs, Peltier modules). DX5100 Controllers have a bi-directional (heating and cooling) PID regulation with PID Auto-Tune function. Besides the PID regulation additional modes of operation are realized in the Controller: DC voltage mode, T-regulation and programming of an object temperature behaviour with time.

SPECIAL EQUIPMENT FOR TEM ANALYSIS AND TESTING

◻ Detailed “deep” TEM analysis

◻ TE Coolers qualification tests

◻ TE Coolers acceptance tests

◻ TEC operating mode analysis

◻ Power consumption research

◻ Testing in Vacuum and dry air

◻ Comparison analysis of TEC vendor estimations

◻ Detailed TEC analysis at specified conditions

◻ Comparison analysis of multiple TEC sources

Hi-end professional R&D systems for comprehensive analysis of TE Modules and TE Materials. It allows to measure all TEC key performance parameters and power consumption under specified conditions. Expert laboratory R&D systems that provide automatic measuring and full specifications of TE modules and materials in one measuring cycle. Perfect for acceptance, qualification and research testing of single- and multistage TE modules.

EXPRESS ANALYSIS WITH Z-METERS - FEATURES AND ADVANTAGES

◻ Simple and quick TE module testing

◻ Suitable for mounted TEMs

◻ Perfect for “Before-After” testing

◻ Express testing of TE modules with Terminal

Wires and WB contacts

◻ ACR Resistance Measurement

◻ Figure-of-Merit Measurement

◻ Time Constant Measurement

◻ Results normalization for required ambient

temperature

Thermoelectric Modules (TEMs) are solid state devices with very long maintenance-free lifetime. Modern thermoelectric modules provide more than 25 years of continuous operating at normal conditions. However mounting procedures and/or improper handling may increase the risks of TEM damages.

Z-Meters are the best solution for thermoelectric modules express quality control and performance testing.